Gold Leaching Tank Design. This speed increase.

Leaching Tank 3d Cad Model Library Grabcad

There are various types of adsorption tanks.

. This reduction in leach time ultimately resulted in lower gold recovery. Sand for leaching is separated from slime in cones V boxes classifiers and in collecting vats filled by distributorsthe overflow in each case being slime or finer portion of the ore. Leaching often gold is the process of extracting a soluble constituent from a solid by means of a solvent.

Gold Leach Tank Aeration Gold Leaching Gas Injection and Bubbles The processing of low-grade gold ores is largely made possible through the use of the cyanide leaching process. Open tank leach processes a natural progression has been to further accelerate leach kinetics through the use of MMS leach columns. The leaching of gold can be conveniently represented by the Elsener equation.

To get more agitation the agitator impellers were sped up. 1 Although air agitated leach tanks were commonly used in. This design problem caused solids to build up around the walls and bottom of the leach tank reducing the effective size of the tank and lowering the actual leaching time for the active slurry.

This design problem caused solids to build up around the walls and bottom of the leach tank reducing the effective size of the tank and lowering the actual leaching time for the active slurry. I-131 radioactive tracer was used to meas-ure the RTD of aqueous phase in the tanks. A good vat leach tank has a 100-200 mm thick layer of bricks or brick sized rocks at the bottom packed a small distance apart 10-50mm so that channels for solution flow is created.

Its for gold extraction with double impeller uniform mixing low energy consumption. Volume 6-1740m3 Application Double impeller leaching stirred tank is suitable for gold leaching adsorption and other mixing operations with small specific gravity low viscosity slow settling speed ore particle size more than 90 in 200 mesh and pulp concentration less than 45. The whole adsorption operations carried out in the adsorption tank carbon slurry tank.

Before leaching the pH of the pulp is normally adjusted to a value of around 9511 to ensure minimum loss of cyanide as hydrogen cyanide. Enviro-Septic amp Simple-Septic Leaching Systems. Gold leaching tank design You will need a steady hand for this eye catching nail design nonetheless its oh-so worthwhileIf you dont have a gentle hand while there are plenty of nail stickers stamps or head on to your neighborhood nail salon so they can replicate it for you.

Activated carbon adsorb gold and become the loaded gold carbon the loaded gold carbon lift into the. Leaching plants faced with increased tonnage coarse up to 316 solids feed longer retention time erosion corrosion and the high cost of space must be compact simple and highly efficient. Leaching tank STEP IGES 3D CAD model GrabCAD.

The Leachox Refractory Gold Process The Testing Design Installation and Commissioning of a Large Scale Plant at the VASGOLD Gold Mine Kazakhstan. Leaching Tank Introduction Cyanide leaching stirring equipment. Leaching Plant Design.

Takes place in a series of agitated leach reactors or pachucas. The engineer faced with the obvious economy of using a few large agitators compared to many smaller units must also. The Leachox Refractory Gold Process The Testing.

- To get more agitation the impellers were sped up. Pump slurry ore into the double-impellers leaching tanks there are always 6-8 tanks working togheter. The impeller coated by rubber long service life.

Place a layer of hesian cloth or plastic bags with small holes all over on top of the bricks and then pour coarse river sand on the cloth layer to a depth of 200. This leaching tank is designed to mix gold particles inside the slurry with carbon and cyanide in CIL plants. Leaching agitation tank is a leaching equipment for cyanide leaching by referring the USA technical design.

Vat leaching is carried out in vats ranging in capacity from 30 to 1200 tons. As a rule leaching is a simple. Adding activated carbon to the fully leaching pulp and the activated carbon will absorb the gold in the cyanide pulp then become the gold-bearing carbon.

The goal of any leaching process is to selectively bring a desired mineral into solution in order to efficiently separate it from the solid waste material. Add cyanide solution into first one or two leaching tanks add activated carbon into the rest gold leaching tanks. Vat Leaching of Finely Crushed Gold Ore.

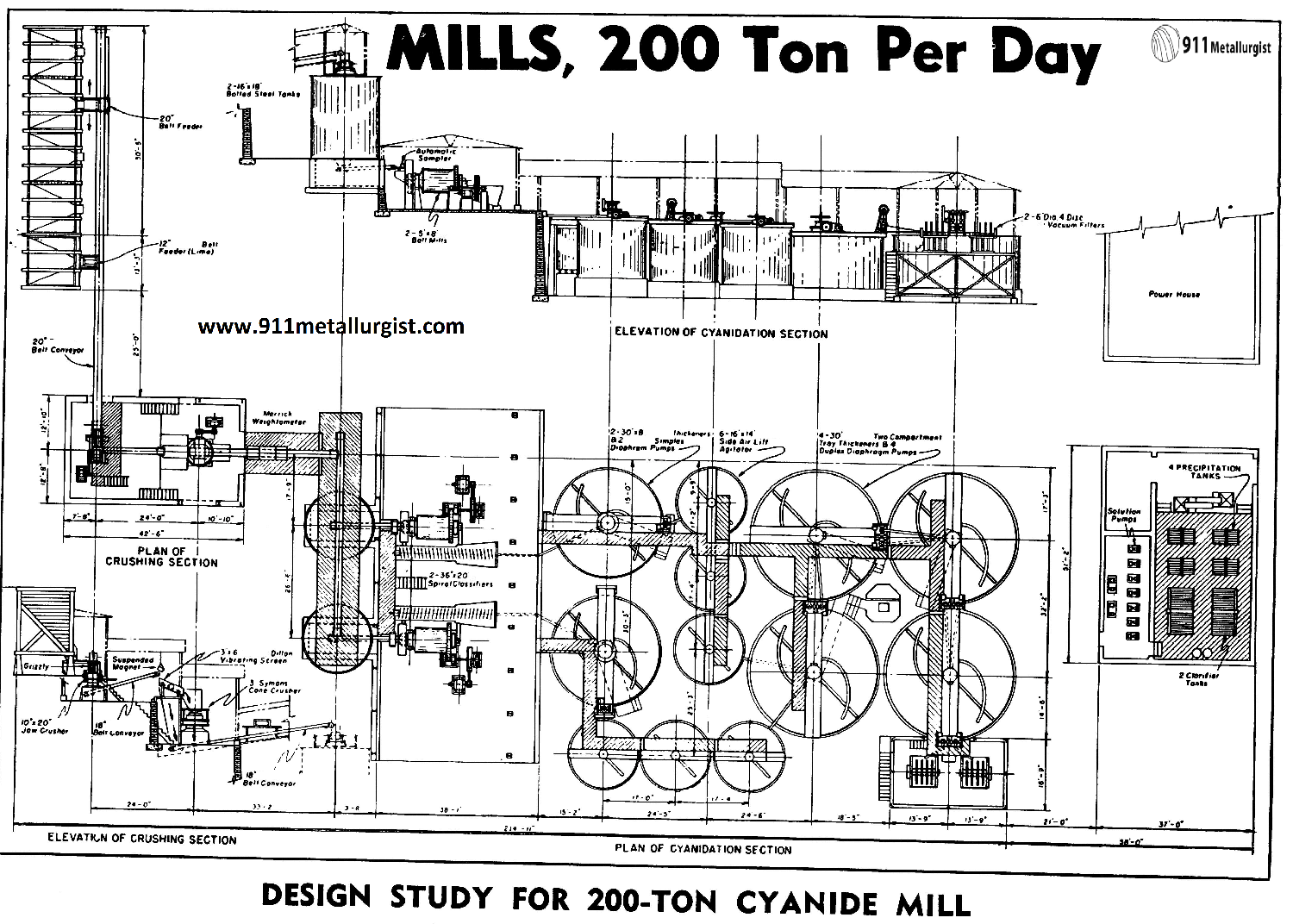

In extractive metallurgy of gold it is the process of dissolving a certain mineral or minerals from an ore or a concentrate or dissolving certain constituents from materials such as a calcines mattes scrap alloys anodic slimes etc to achieve either one or. From the results of the investigation the tanks-in-series model with. A typical installation is depicted in Figure 30 below.

This reduction in leach time ultimately resulted in lower gold recovery. In order to validate design data after process intensification at Damang gold processing plant experimental RTD investigation was conducted in a series of gold leaching tanks.

Pdf Improving The Process Performance Of Gold Cyanide Leaching Reactors Semantic Scholar

Improving The Gold Leaching Process Of Refractory Ores Using The Jetleach Reactor Sciencedirect

Figure 2 From Determination Of Flow Patterns In Industrial Gold Leaching Tank By Radiotracer Residence Time Distribution Measurement Semantic Scholar

Leaching Tank 3d Cad Model Library Grabcad

Radiotracer Investigation In Gold Leaching Tanks Sciencedirect

0 comments

Post a Comment